Project runtime: 01.09.2023 – 31.08.2026

2024-02-29_BMBF_KickOff_AnAttAl

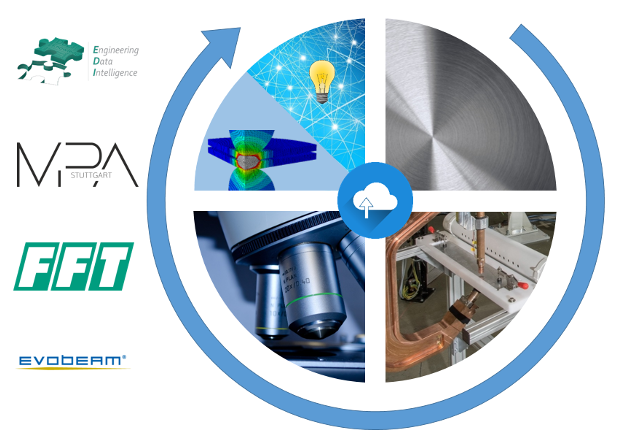

Aluminium alloys have a very high lightweight construction potential and are therefore becoming increasingly important. However, the use of aluminium alloys is severely restricted as there is often a lack of knowledge about joining. The inhomogeneously growing oxide layer, the passivation layer, the required dry lubricants and adhesives have an immense influence on the welding quality of many welding processes. However, the detailed effects of these factors are largely unknown. On the one hand, this means that reliable joining cannot be guaranteed. On the other hand, materials are scrapped too early because there is no adequate or cost-justifiable test available for the further usability of the material. The aim of the "AnAttAl" project and the participating companies EDI, MPA, FFT and Evobeam is to use artificial intelligence to analyse the influences of the material and its surface properties on the joinability and to predict the joining result. This requires an ontology that describes the available data from measurement, process and simulation, formally records correlations and links them together. Based on this, logic-based inference algorithms should automatically analyse and interpret correlations in order to break down the relationship between process, material and quality. Resistance and electron beam welding are used here as joining applications. If the project is successful, the underlying idea will lead to a tool that increases the use and processing time of aluminium, prevents unnecessary scrapping, reduces the need for "new" material and thus reduces greenhouse gas emissions, which offers major benefits both economically and socially. The active exchange with PMD and the resulting transferability of the findings to other applications will enable Germany to further strengthen its international competitiveness.